Attention

This website is best viewed in portrait mode.

Aerostructure Design & Engineering

Safe, Efficient and Durable

Aerostructure Design & Engineering

Safe, Efficient and Durable

Designing for the Skies Ahead

In aerospace design and engineering, the current trajectory is marked by swift design-to-market times, fewer parts per product, and a strong emphasis on sustainability. Innovative materials and rapid prototyping, such as 3D printing, are critical for maintaining integrity and reducing the weight of aircraft structures, especially as aircraft electrification advances.

This sector faces the dual forces of opportunity and challenge: the demand of faster to market and engineering present the chance to redefine aerodynamics, while the need first time ready designs that endure extreme conditions . Accurate simulations, load calculations are essential for predicting performance and ensuring compliance to stringent standards. The faster to market calls for AI led engineering and knowledge-based engineering (KBE) to the workflow. These complex structures also will demand for special toolings, when it comes industrialization.

Tata Elxsi stands at the forefront of these developments. Tata Elxsi has owned the marquee programs like ISRO's Crew Module Recovery Model (CMRM) and Indian Aerospace OEM's aerostructure for morphing wing UAV. With comprehensive expertise from concept to prototype, we offer a harmonious blend of optimized designs, advanced materials, simulations, and tooling ensuring durable and efficient aerostructures. Tata Elxsi's skilled CAE team is equipped to tackle multi-domain challenges, preparing aerostructures for the demands of modern aviation.

Design and Engineering of Crew Module Recovery Model (CMRM) for ISRO's Gaganyaan Space Mission

“Tata Elxsi has carried out the design and delivered hardware meeting a highly challenging delivery schedule of 6 months, demonstrating excellent program management skills. This has enabled timely commissioning recovery training exercise to meet Gaganyaan mission requirements. ISRO would definitely like to partner in the future for different projects.”

Dr. Umamaheshwaran, Director-HSFC, ISRO

Here’s How We Can Help You

Emphasis on Lightweighting, VA/VE, aerodynamics while balancing the sustainability and emission

- Complete Engineering credentials in aerospace structural engineering, undertaking turnkey programs delivering aerostructures through concepts , design layout, calculations, materials, simulations, mockup and tooling. This enable us to look at Aerostructure wholistically as a commodity.

- Digital twins to accelerate product development and monitor the performance

- Design for manufacturability, serviceability and newest production techniques such as Additive Manufacturing

Expertise on right materials, process for critical aerostructures with a focus on structural integrity, cost and ease of sourcing.

- Dedicated materials and simulations team for metallics and composites, working in synergy.

- Hands on knowledge with the library of space grade and aero grade materials for the future aircrafts.

- Knowledge Based Engineering(KBE), CAD & CAE Automation driven by AI for shorter development cycles.

Advanced Simulations for aeroelasticity, fatigue, fracture and ascertaining the right load conditions.

- Advanced CAE team with profound knowledge on multiple domains of Aerodynamics, CFD, NVH, Acoustics, Structural , Thermal and other multi physics with a focus for Aerostructure Design

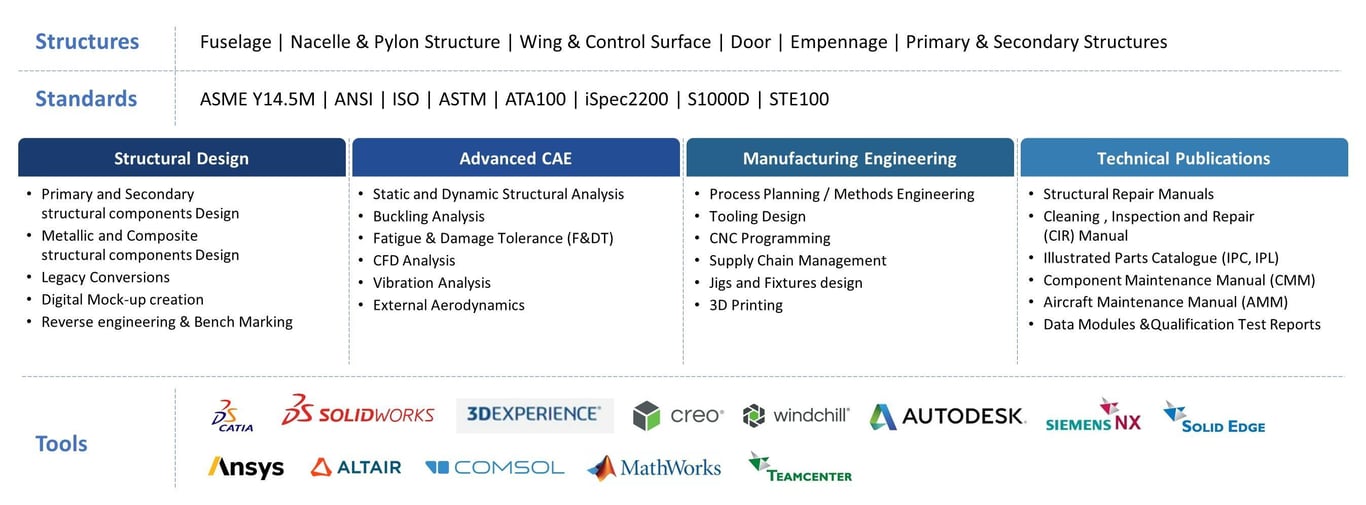

Service Framework

Why Tata Elxsi?

- Extensive knowledge base on Aerospace grade composite and materials

- Deep focus on value engineering, compliance and manufacturability

- Knowledge Based Engineering (KBE) to automate repetitive design tasks

- Turn-key model delivery - Concept Design till Prototyping under one roof

- Supported by global network of own Industrial Design Studios and extensive partner ecosystem.

- Program Ownership including the configuration management

Subscribe

To subscribe to the latest updates & newsletter