Attention

This website is best viewed in portrait mode.

-

industries

- automotive

-

Battery Pack Development

Battery Pack Development

Battery Pack Development

Engineering Excellence in Battery Pack Development

In the ever-evolving landscape of Electric Vehicles (EVs), the approach to custom battery pack design is undergoing a transformation. This shift is driven by a long-term vision to gain more control over the value chain, including Battery Management Systems (BMS) and in-depth design capabilities. This forward-thinking approach aligns with the industry's trend towards greater autonomy and self-sufficiency in battery development.

OEMs pursue diverse battery development strategies. Legacy Auto OEMs often depend on major battery manufacturers, while new-age OEMs aim to control BMS and on-site battery design.

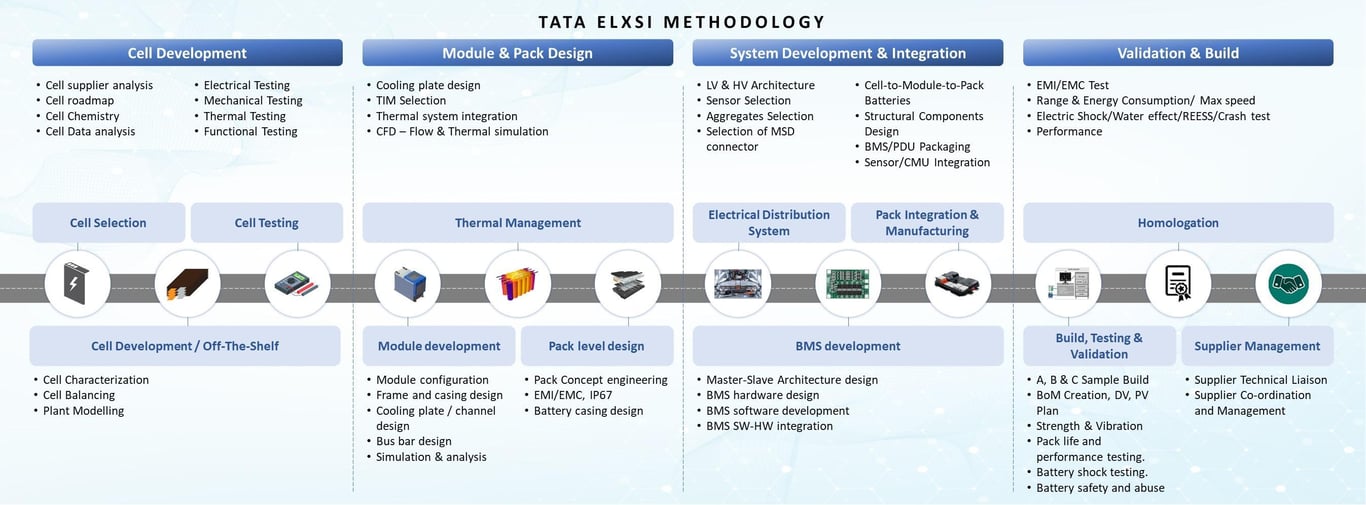

Tata Elxsi focuses on promoting in-house innovation and collaborating with Battery Tier 1 and 2 suppliers to expedite delivery. We excel in managing complete battery programs for global OEMs, with capabilities spanning cell selection and manufacturing support, ensuring a seamless end-to-end process. This innovative approach transcends battery programs, encompassing a wide range of powertrain efficiency projects. Our industry-leading methodology reduces time-to-market across these diverse initiatives.

Here's how we can help you

- Battery Design Services: Battery design services across the entire life cycle, including System Engineering, Software and Hardware Development, Validation and Verification, Mechanical Design, and Reference Designs.

- Accelerators: Providing Battery Models, BMS (Battery Management System) Software and Hardware reference designs, battery twins, and Modular, Scalable Solutions.

- Pack Design: Cell to Pack Module design, Frames, Enclosures, busbars, and cooling systems.

- Simulations: Simulation services, including Thermal Management, CFD, Structural Analysis, and a wide array of simulated stress tests, including nail penetration, thermal runaway, side pole impact, and more

- BMS Development: ASW (Application Software), BSW (Basic Software), CDD (Complex Device Driver), Functional Safety (FuSa), BMS Controller algorithm, and plant models.

- Validation: Functional Testing, System Validation, Packaging, and Vehicle Integration to ensure a seamless battery design process. BMS HILs facility and a robust physical testing ecosystem that contribute to our commitment to excellence.

Service Framework

Why Tata Elxsi?

- Cutting-edge labs and robust supplier ecosystems across all stages of battery development for large-scale production programs.

- Comprehensive turnkey programs across diverse domains, including mechanical, electrical, electronics, and software, fostering seamless cross-departmental synergy.

- Exceptional flexibility in cost and delivery models designed to precisely align with various OEM requirements.

Subscribe

To subscribe to the latest updates & newsletter