Engineering the Future of Rail

In the face of escalating passenger volumes, rail operators face the challenge of improving frequency and safety standards amid fierce competition from alternative transport modes. Meanwhile, the growing prevalence of mobile-friendly networks on trains and at stations heightens the need for robust cybersecurity measures. These factors drive the global rail industry toward automation, advanced railway signaling, and digital transformation.

Through driverless operations, CBTC-powered signaling, and integrated design, stakeholders optimize service availability and passenger experience. By leveraging MBSE (Model-Based Systems Engineering) and next-gen technologies like AI, IoT, and machine learning, operators enhance network capacity, streamline operations, and deliver an improved commuting experience.

Developing an intuitive VR experience platform

Rolling Stock and Systems challenges

Informed by three decades of domain expertise, we deliver robust global solutions in rail, design, and engineering. Our proven MBSE methodologies, integrated early in the v-cycle, drive cost-efficient, error-free outcomes. Leveraging cutting-edge frameworks, IP-driven innovation accelerators, and flexible engagement models, we swiftly adapt to evolving demands. Holistic human factors, and service design further elevate passenger comfort, brand perception, and operational efficiency.

Here’s How We Can Help You

Enhance Rolling Stock Performance

- Leverage a platform-based approach for standardized requirements, feature requests, and issue tracking across geographies.

- Integrate automated image-based inspection for rail tracks and platforms, boosting operational efficiency.

- Employ robust MBSE early in development, reducing complexity and accelerating time-to-market.

- Deploy Automated Surveillance and Monitoring solutions that detect anomalies and enhance passenger and operator safety.

- Incorporate hardware-in-loop simulation to test and validate safety-critical systems before full-scale rollout.

- These measures minimize downtime and safeguard brand reputation.

Accelerate Digital Adoption

- Integrate AI, IoT, and advanced data analytics to streamline operations and generate actionable insights.

- Adopt driverless technologies and CBTC solutions to optimize headways, increase throughput, and meet evolving commuter demands.

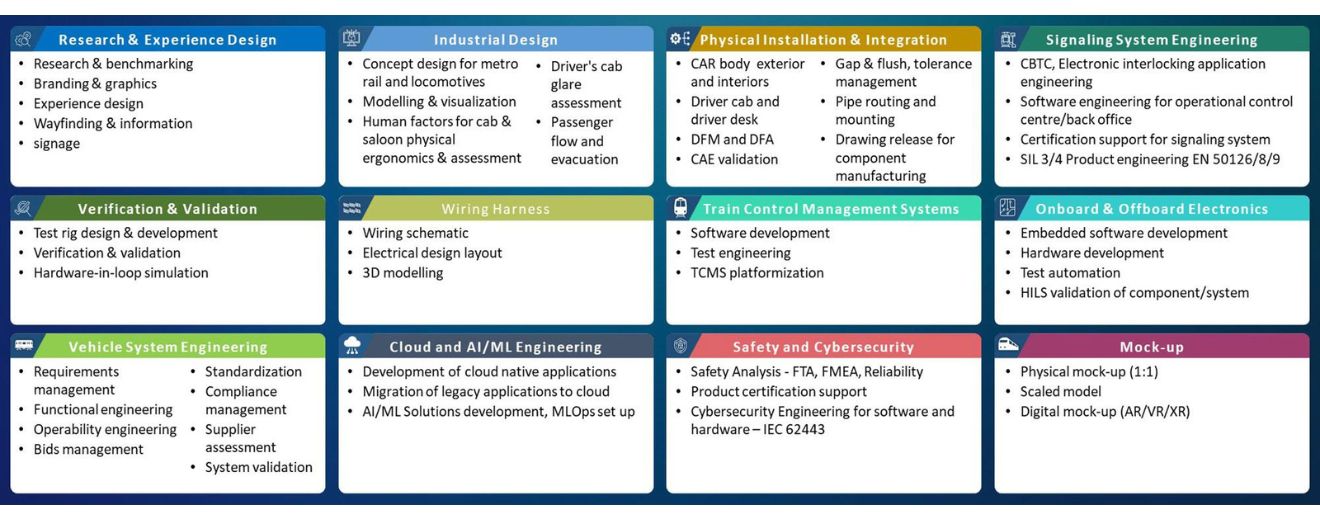

Service Framework

Our Rolling Stock and Systems service framework visually integrates the entire rail ecosystem, from conceptualization to operation. It aligns MBSE methodologies, product development lifecycles, and digital enablers like AI and IoT. This holistic view ensures consistent compliance with safety standards, streamlines collaboration among stakeholders, and accelerates seamless rail solutions across global networks. It fosters scalable growth for the rail industry.

Next-Gen Signaling Solutions

Achieve optimal headways and enhanced safety with CBTC and other state-of-the-art railway signaling systems. Our solutions maximize track capacity while minimizing operational risks through precise train detection and obstacle recognition. By integrating advanced analytics, operators gain real-time visibility, enabling swift decision-making and improved commuter satisfaction. Seamless integration ensures consistent performance.

Advanced Automation and Control

Empower driverless trains and semi-automated operations through robust control algorithms, MBSE-driven designs, and hardware-in-loop simulations. Our approach reduces human error and supports response times in critical situations. Testing and validation guarantee compliance with safety regulations, while predictive maintenance capabilities minimize downtime and optimize operational efficiency. Scalability is built-in from inception.

Integrated Cybersecurity

Safeguard onboard and wayside systems from digital threats with multi-layered cybersecurity strategies. Our approach includes robust encryption, vulnerability assessments, and real-time intrusion detection systems. By integrating IoT device management and advanced analytics, operators maintain system integrity, protect passenger data, and ensure uninterrupted service, fostering trust and resilience. Monitoring fortifies defenses.

Why Tata Elxsi?

- Three decades of domain expertise delivering turnkey rail, design, and robust engineering solutions truly globally.

- Proven MBSE methodologies at the left of v-cycle for cost-efficient, error-free development lifecycles in rail.

- Cutting-edge frameworks, solution enablers, and an IP portfolio accelerating innovation across global markets very quickly.

- Holistic human factors, industrial, and service design elevating passenger comfort, brand perception, and operational efficiency.

- Flexible engagement models and scalable teams empower rapid response to evolving demands and project complexities.

Information Hub

-

What are the major trends influencing Rolling Stock and Systems today?

Key trends include the push for driverless operations, adoption of advanced signaling systems like CBTC, and a heightened focus on cybersecurity amid growing digitalization. MBSE is also gaining traction for streamlined design and development, while next-gen technologies such as AI and IoT are reshaping operational strategies. These shifts aim to enhance safety, improve passenger experience, and increase capacity to meet escalating demand.

-

How do driverless trains impact operational safety and efficiency?

By removing or reducing human error, driverless trains can operate with greater precision, leading to shorter headways, increased capacity, and improved service frequency. Automated systems continuously monitor speed, track conditions, and train spacing in real time. This approach not only boosts punctuality and reduces energy consumption but also provides a safer environment for both passengers and operational staff.

-

Why is MBSE important for Rolling Stock development?

MBSE enables a holistic, model-driven approach that unifies stakeholders across engineering, design, and manufacturing. By capturing requirements, behaviors, and constraints within a single model, it helps identify issues earlier in the lifecycle. This reduces rework, lowers costs, and accelerates development timelines. MBSE’s collaborative nature ensures consistent alignment with safety standards and functional objectives throughout the v-cycle.

-

What role do next-gen technologies like AI and IoT play in rail?

AI powers predictive maintenance by analyzing real-time sensor data, anticipating component failures, and optimizing resource allocation. IoT connects onboard devices and trackside infrastructure, enabling seamless data exchange and remote monitoring. Together, they improve operational efficiency, enhance safety through constant oversight, and deliver personalized passenger experiences. These technologies also pave the way for advanced automation in rail networks.

-

How can operators ensure cybersecurity for onboard and wayside systems?

Operators should adopt a multi-layered cybersecurity strategy involving encryption, robust access controls, and continuous vulnerability scanning. Real-time intrusion detection, combined with IoT device lifecycle management, helps isolate threats before they escalate. Regular risk assessments, staff training, and compliance with industry regulations further strengthen defense. Partnering with specialist providers ensures updates remain current and effective.