Attention

This website is best viewed in portrait mode.

Aerospace Electrification

Enabling Clean & Efficient Operations

Aerospace Electrification

Enabling Clean & Efficient Operations

Powering the Roadmap to Sustainable Aerospace

The electrification encourages innovations in Electric Propulsion system, Battery technology from fuel cell material for storage, optimizing the packaging, Power management and finally the electric controls. This solidifies the roadmap for the aerospace sustainability goal.

The industry faces challenges in availability of the right fuel cell that supports the thrust needed for eVTOL (electric Vertical Take-Off and Landing) and long endurance. The choice of fuel should be within the minimum weight takeoff constraints and form factors of a tiny UAV (Unmanned Aerial Vehicle). Designing an efficient cooling system to overcome such concerns is required to manage the high voltage and thermal conditions. Conversion of power and distribution to different sub-system efficiently is another significant challenge.

Tata Elxsi offers product engineering services for the selection of the right fuel cells, mechanical design for effective packing of the cells, and a battery management software solution. The electrification solutions are shaped and matured in various industries, and with this experience, we could help boost the aerospace suitability journey.

Here’s How We Can Help You

Managing the size and weight of batteries, which limits the Electric aircraft performance, along with the best use of Battery technology

- Selection of Battery Technology, Modular Battery Frame, Battery thermal solution, Model based performance prediction, Concept package automation, Scalable BMS HW/SW, Fuel Cell Controller, Fuel Cell Packaging etc.

Engineering capabilities for electric motors which reduces harmful emissions and offers a lesser operational cost

- Model Based System Engineering- Requirement Modelling, Actuator Modeling, Simulation, Model In-Loop Testing, Motor control algorithm development- Motor Plant Model development, Control software development, Algorithm optimization & Verification, Industry standard compliance, Digital Twin for Battery, Rapid Control Prototyping- Drive/Motor Control unit, and Integration testing

Build actuators from hydraulic to Electric Complying to the form factors and specification

- Design and Development of Actuators, fabrication through local vendors, integration support, Certification of Electric Actuators, Identification of Vendors, Production Support.

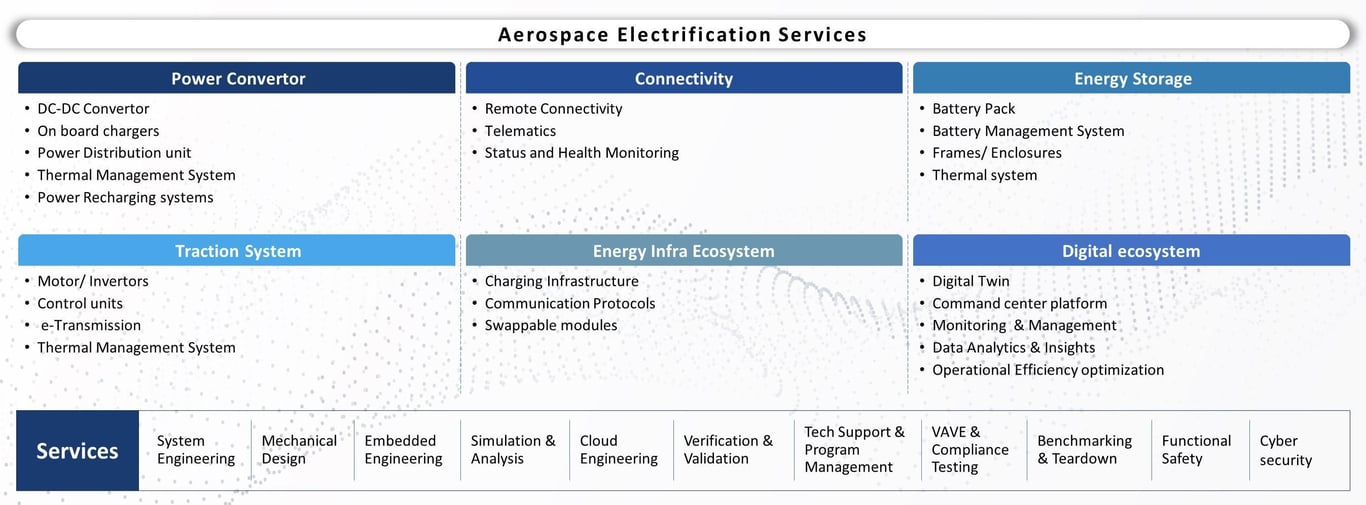

Service Framework

Why Tata Elxsi?

- Providing comprehensive engineering services, which include software, hardware, mechanical, and cloud deployment.

- We are experienced in developing solutions with the highest safety standards, ARP4761 compliant.

- One-stop solution for Electrification and eVTOL (electric Vertical Take-Off and Landing) Ecosystems: Embedded, Mechanical, and Digital.

April 17, 2023

Press Releases

Tata Elxsi Collaborates with the Indian Institute of Technology- Guwahati (IIT-G) to foster EV Technologies

Case Study

Effective Thermal Management and Cooling in eVTOL Thermal monitoring and controlling system.

Case Study

Higher Energy density for Batteries in eVTOL Lithium-Ion (Li-Ion) and Solid-state batteries

Subscribe

To subscribe to the latest updates & newsletter